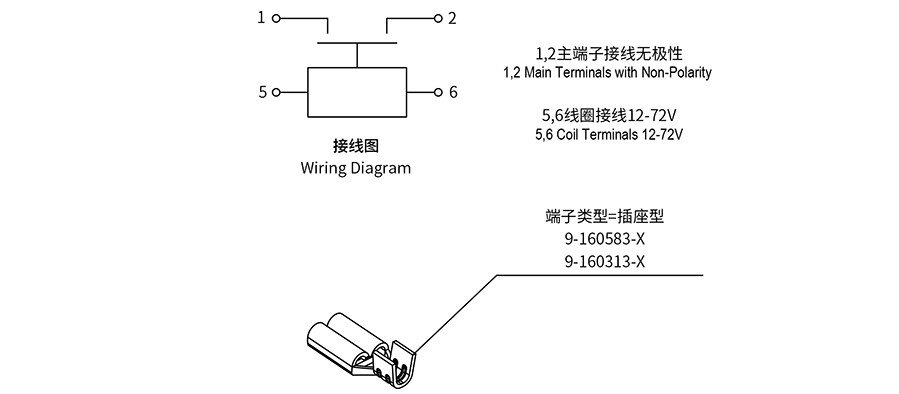

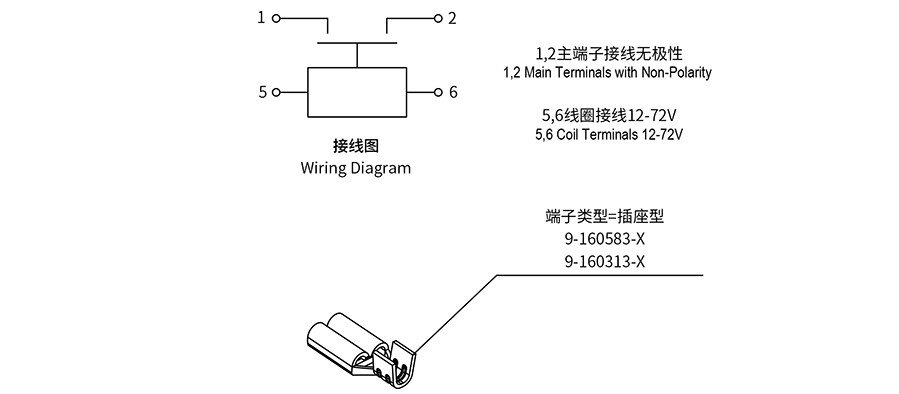

Wiring Diagram

Usage Cautions

1、 This document is only for customer selection reference, AOKAI has tried the best to ensure the accuracy of the information in this document. Product specifications and parameters may be changed due to product improvement etc., they may be inconsistent because of not updated in time. For the specific parameters and performance of each product, please refer to the samples provided by AOKAI and the corresponding signed and controlled specification.

2、 Regarding the application of this product, please select the matching product according to your specific use conditions and environmental requirements when selecting the product. If the requirements are not clearly specified, please contact AOKAI to obtain more technical support.

3、 When installing and using this product, regardless of wiring or fixed installation, it is required to use anti-loose spring washers.

4、 The torque for installing fasteners should be within the standard range required by this specification. It may cause the unstable installation or damaging the product if the torque is lower than the minimum torque or higher than the maximum torque.

5、 Do not install the contactor in places with strong magnetic fields (such as transformers or strong magnets), or close to objects with thermal radiation. It is recommended to use it with a cooling fan.

6、 It is forbidden to use the product that have been dropped from a high place (height≥30cm)

7、 It is forbidden to use the product in an environment with oil pollution, especially before wiring, it will seriously affect the main terminals conductivity if they are polluted by oil pollution, and affect the product life.

8、 It is forbidden to use the product beyond the rated electrical life. When the rated electrical life is reached, although the product can continue to work, there is a risk of failure, explosion, and burning because of non-breaking.

9、 This product cannot be used as a protector, and the circuit must be connected with a protector in series when using.

10、AOKAI only does the resistive electrical life verification and quality assurance. When the product is used in an environment

with inductive load or capacitive load, it is recommended that the circuit should be connected in parallel with a surge protection device.

11、After continuous work, restarting immediately after disconnection will affect the pull-in voltage because the product is in a hot

state, and the pull-in voltage will increase, which is a reasonable phenomenon.

12、It is strictly prohibited to wiring when power on.

0086-18968763905

0086-18968763905 akelectric@ak-elec.com

akelectric@ak-elec.com 0086-18968763905

0086-18968763905 MESSAGE

MESSAGE